KTK MOULDTEC

.

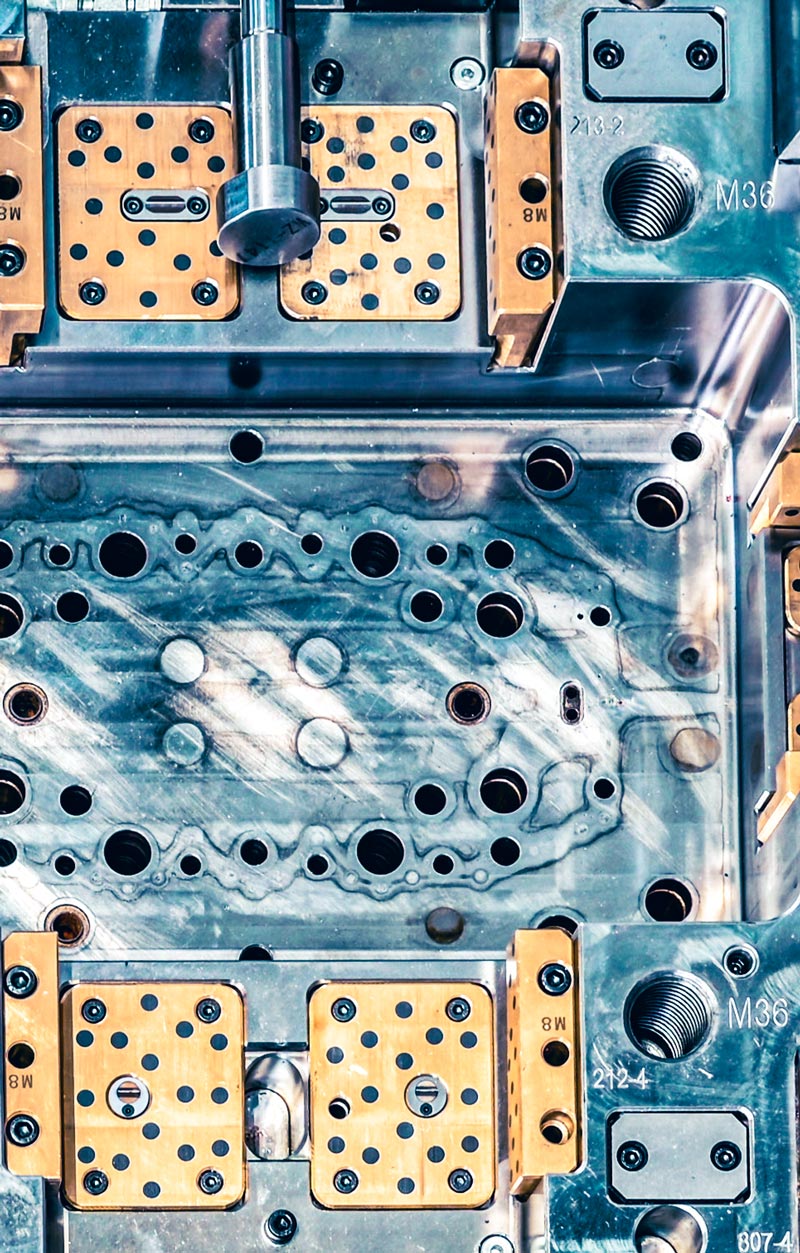

Our tool service focus

Quality-Check

Tool change

Tool maintenance & repair

Nowadays, the tool service for injection molds & co. is one of the most important components of your company's success. After all, series production must function with maximum production capacity utilization and reliable quality.

We at KTK are happy to personally take over the tool service and follow-up support for our joint projects. Through final quality checks, individual tool modifications and maintenance including repairs, we ensure the desired, flawless tool function and guarantee you the best possible output.

Project planning & mold construction for injection molds

Prototype tool in steel

stack molds

1k/2k series tools

Inmold & overmold tools

Small-batch plastic production in Asia with delivery to Tier One from the German site

Second stage change management

In second stage change management for injection moulds, advanced measures are taken to further optimize production processes. This includes fine-tuning tool parameters such as temperature, pressure and speed to improve the quality of injection molded parts. In addition, new technologies can be introduced to increase efficiency and reduce waste. Second stage change management is crucial to maintaining competitiveness in the injection molding industry and meeting the demands of the market.

Fine-tuning of tool parameters such as temperature, pressure and speed

Reduction of rejects and errors

Adaptation to changing market requirements

Implementation of new technologies to increase efficiency

Optimizing the quality of injection-moulded parts

Continuous improvement of production processes