KTK MOULDTEC

.

Our services at a glance

Our core competencies

Automotive - Interieur & Exterieur

Home Appliance

Individual solutions

Tool design

Our team has been designing injection molds for automotive suppliers and the medical and household appliance industries for many years. Tool design is our main field of activity. Most of our customers are TIER 1, TIER 2 and toolmaking companies. In accordance with the customer's specifications, the article data is subjected to an intensive examination for plastic and tool-compatible feasibility upon receipt. Adherence to deadlines and quality are the top priorities for our tool designs. We accompany our customers through the entire production process right up to the acceptance of the tool and are always on hand with help and advice, even in difficult situations.

We build for you:

● Conventional injection molding tools up to 4

● 1K/2 injection molds

● Insert - Molding

● Dice tools

● stack molds

● Insert tools

● Gas injection molds (GID)

● Hybrid tools (organosheets)

CAD system / CAM programming

The current version of the VISI CAD system is used for 3D tool designs. It is possible to import and export CAD data via the STEP interface in such a way that it can be imported 1:1 into the CATIA system, for example, with a full tree structure according to the standard specifications, naming conventions and colors, and processed further there.

Using state-of-the-art CAM systems, the various tool components are processed in virtual processing machines and released for production in the company network after being checked by the employee.

Contract work

Component development

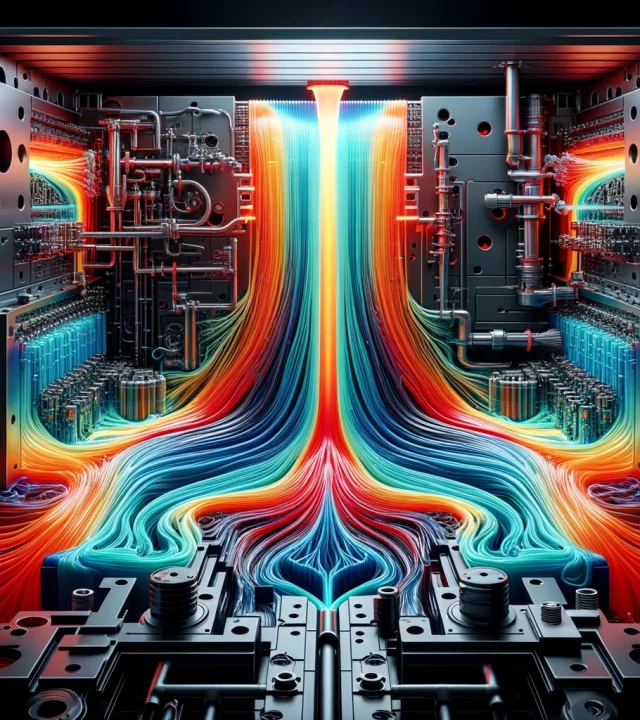

Flow analyses

Parts production

The production of parts and assembly of injection molds is an important step in industrial production. It involves the production of tools that are used in the injection molding technique to form plastic parts. This process includes manufacturing the tool components, assembling these components into a functional tool and, if necessary, fine-tuning for optimal performance and quality of the manufactured parts. Nowadays, a large number of products are manufactured in Asia. The advantages of quality production in China are obvious - lower costs and faster time to market. KTK is your reliable partner for parts sourcing from Asia. To ensure our highest quality standards, our experts are on site from the start of the project and accompany every single step. After small series production, the parts are transferred to our German site, where the final quality check including modifications is carried out. We are then happy to deliver your desired products directly to the production line!